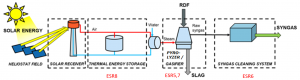

Work package 2 studies the thermal conversion of RDF (i.e. the light fraction produced in work package 1 through mechanical processing, composed of plastics, wood, etc.), for the production of synthetic gas, slags (so-called plasmastone) or ashes (depending on the thermal process) and metals. The 4 PhD topics have been linked in a novel thermal conversion process for RDF, shown in the figure below.

WP results

Download the results of the WP here:

- Final WP report (pdf)

- WP presentation given at the fifth international symposium on ELFM (Feb. 2020) (pdf)

Results per ESR

Ilman Nuran Zaini (ESR5), based in KTH (Sweden), studies the thermal conversion of RDF through steam plasma gasification. Kinetics of char conversion to syngas, as well as ash melting behaviour have been studied experimentally on RDF samples in lab-scale tube reactors. Gas and tar compositions are analysed.

Yamid Gomez Rueda (ESR6), based in KU Leuven (Belgium), studies the further purification of syngas using plasma tar cracking. A newly developed experimental set-up has been built up. Plasma cracking of naphthalene has been compared with thermal cracking without plasma. The reactor is fed with a polluted synthetic gas using a set of flowmeters able to control the different gases fed and the residence time inside the reactor. The gas composition is monitored and the level of pollutants and their composition is determined.

Katarzyna Jagodzińska (ESR7), based in KTH (Sweden) (ESR position was transferred from ETH to KTH, cfr. below), is studying the pyrolysis of RDF using lab-scale pyrolysis tests. Products are thoroughly characterized, which includes their yields and composition. The last stage of the study is on-going and includes the lab-scale tests on catalytic cracking of volatiles produced during pyrolysis.

Marco Gigantino (ESR8), based in ETH (Switzerland), is developing a thermochemical reactor for thermal energy storage. The energy storage will be used to supply a constant temperature gasification agent to the process. A thermal energy storage system based on high-temperature reversible gas-solid reactions was developed based on both experimental work and modelling techniques. Prospective thermochemical storage materials have been selected and the cycle-to-cycle stability of the systems was investigated. Subsequently, a lab-scale heat storage reactor was designed, assembled, tested and modelled.