Wienerberger & SIM² KU Leuven researchers have studied the potential use of secondary raw material sources, such as mining waste, in building and construction products. The work, which was published in the Journal of Geochemical Exploration, was performed in the framework of the H2020 MSCA-ETN SULTAN project for the remediation and reprocessing of sulfidic mining waste sites.

Increasing demand for building materials

The demand for building and construction materials increases as the world population keeps growing, thus increasing the need of shelter, as a basic human need. This increasing demand for building and construction materials not only leads to higher demand for primary raw materials, such as clay or sand, but also to higher emissions of carbon dioxide which contribute to the greenhouse effect leading us to the biggest and ongoing threat to life on earth: global warming.

The potential use of secondary raw material sources, such as mining waste, in building and construction products not only minimises the ecological footprint of this sector but also minimises the pressure on the primary raw material sector, hence fostering the transition towards a more resource-efficient and sustainable world.

Mining waste as input material for roof tiles and blocks

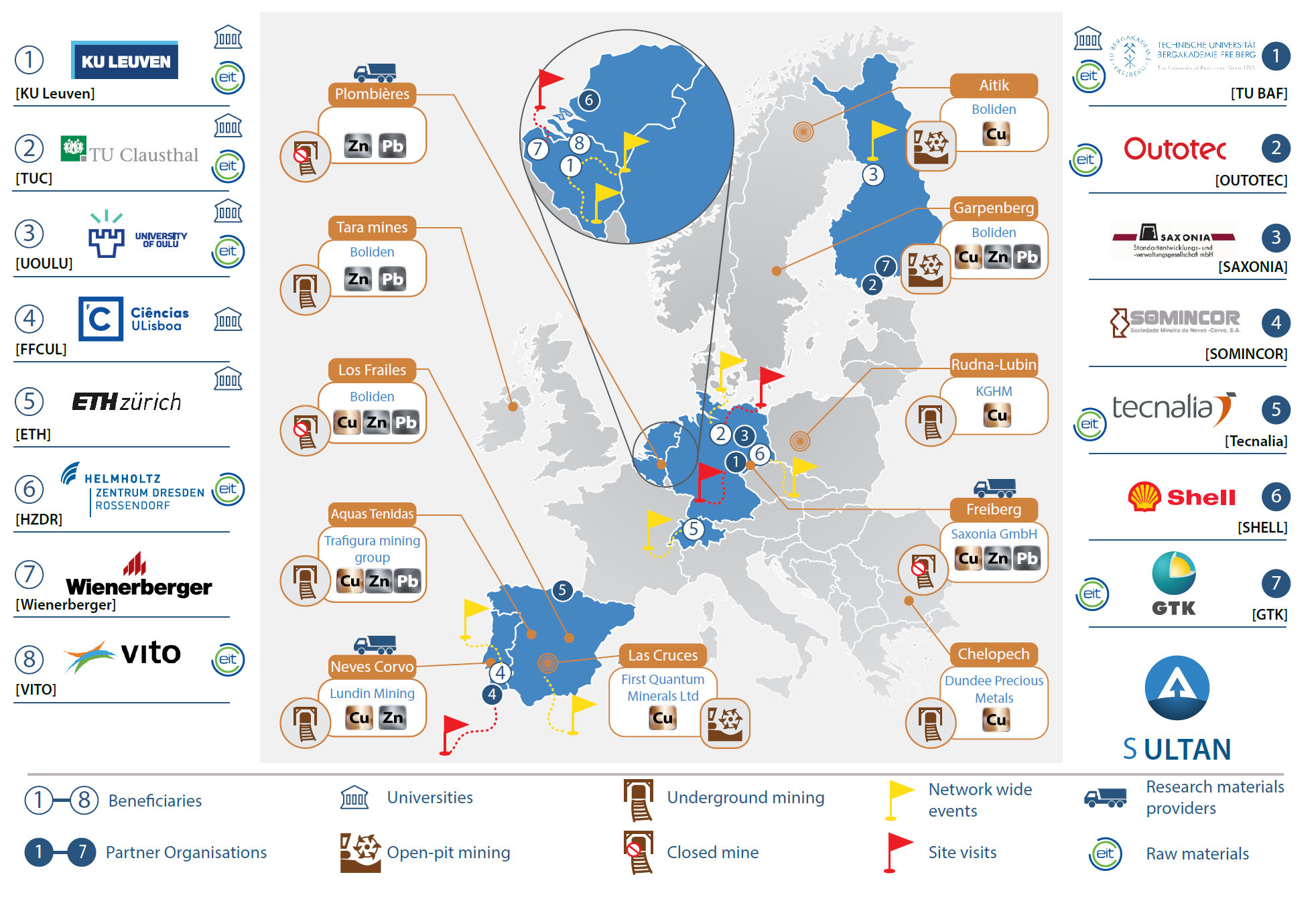

The goal of this study is to evaluate the potential use of uncleaned sulphidic mining tailing material from two inactive Zn-Pb (Plombières, Belgium) and Cu-Zn-Pb (Freiberg, Germany) mines, and uncleaned sulphidic mining waste rock material from an active Cu-Zn mine (Neves-Corvo, Portugal), in ceramic roof tiles and blocks taking into account production parameters (shaping, drying and firing processes), product quality (technical, aesthetical and chemical properties) and environmental compliance of secondary raw materials for use as building products.

After a detailed physical, mineralogical, chemical and thermal characterisation of the materials, blends for ceramic roof tiles and blocks were made by partly or totally replacing some primary raw materials (mainly clay and sand) by 4 different mining waste materials. Roof tile and block blends containing 5 wt% and 10 wt% mining waste materials, respectively, were produced on a lab scale.

The required technical, aesthetical and chemical properties for each ceramic product were evaluated. Freiberg tailing and Neves Corvo waste rock materials presented considerable amounts of sulphur and metal(loid)s. Moreover, technical, aesthetical and chemical properties of the blends using these mining waste materials were not satisfying and Neves Corvo waste rock materials have the disadvantage of needing a mechanical treatment (grinding and sieving) before integrating them into the ceramic blends.

Therefore, the Freiberg tailing and both Neves Corvo waste rock materials are considered to be less suitable to replace primary raw materials in ceramic roof tile and block blends, even in smaller amounts (5 wt% and 10 wt%, respectively). In contrast, Plombières' fine tailing material was characterised by a low sulphur and metal(loid) content as well as satisfying environmental performance. The roof tile and block blends, in which Plombières tailing material was integrated, showed satisfying technical, aesthetical and chemical properties. Consequently, Plombières' tailing material can be considered as the best fit to partly or totally replace some primary raw materials in both ceramic roof tile and block blends.

Full reference paper

F. Veiga Simão, H. Chambart, L. Vandemeulebroeken, V. Cappuyns, Incorporation of sulphidic mining waste material in ceramic roof tiles and blocks, Journal of Geochemical Exploration, Volume 225, June 2021, 2021, 106741, DOI:10.1016/j.gexplo.2021.106741.

Acknowledgements

This project has received funding from the European Union's EU Framework Programme for Research and Innovation H2020 under Grant Agreement No 812580.