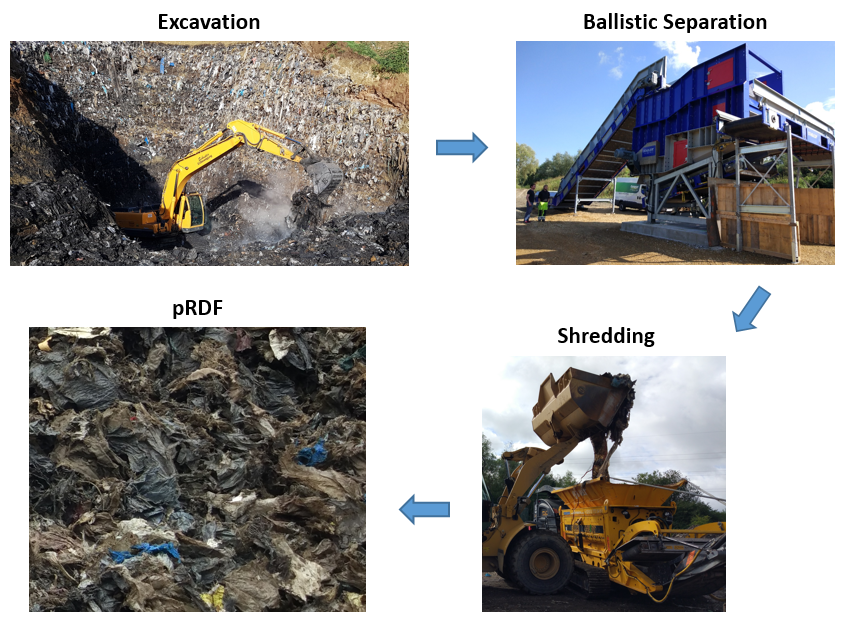

In our project 15 early state researchers (ESRs) work together to produce energy from landfill material using a wide variety of technologies. Beginning with excavations and mechanical processing we generate an intermediate product for this purpose, called potential refuse derived fuel – pRDF (compare Figure 1). This pRDF mainly consists of films and plastic bags (2D-fraction) and is supposed to be utilized thermally via plasma gasification. The remaining residues of plasma gasification should be transformed into cement substitute.

Figure 1: Production process of pRDF in NEW-MINE project

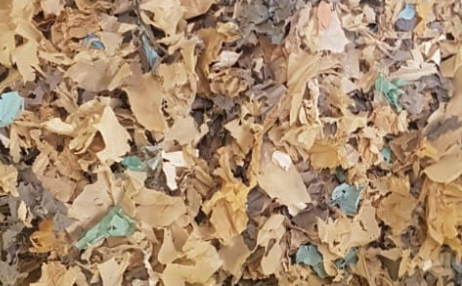

To use a technology like plasma gasification for energy production it is crucial to agglomerate or pelletize the films and bags, otherwise this material could not be used in the thermal conversion process we strive for. In an attempt to produce such agglomerates I dried and shredded a sample of this 2D-fraction further down to a maximum grain size < 20 mm (compare Figure 2).

Figure 2: Shredded and dried 2D-fraction

To agglomerate this fraction a share of this sample was pressed to pellets. These pellets looked great on the surface but inside a relatively high pore volume could be observed (compare Figure 3 – bottom).

Figure 3: Top – Pellets from 2D-fraction, Bottom – Cross section of Pellets

The high amount of air trapped in the pellets reduces the suitability of these agglomerates for thermal treatment. So, in an attempt to reduce the amount of air inside and to increase the heating value of the pellets, the 2D-fraction was screened with a 2.8 mm sieve reducing the amount of dust and little stones that were attached to the foils and bags prior to the drying and shredding process. Afterwards the refined 2D-fraction was agglomerated under heat and pressure once again. This time, to my satisfaction, very low pore volume could be observed (compare Figure 4).

Figure 4: Top – Pellets from refined 2D-fraction, Bottom – Cross section of Pellets

Now we are able to use pellets from landfill mining material for further research on thermal recovery in the NEW-MINE project!

About the Author:

Bastian is our ESR 3. He is German, has a master in waste management engineering and works at the Montanuniversitat in Leoben. His research focuses on the utilization of sensor based sorting equipment in order to separate valuable particles (e.g. metals or plastics) from landfill material during mechanical processing. He studies the influence of defilements on sensor based sorting and on wet-mechanical treatment in order to reduce defilements, creating high quality recyclable material. If he’s not in the university’s lab’s, you can most probably find him trail running, swimming or rock-climbing. Bastian is our ESR 3. He is German, has a master in waste management engineering and works at the Montanuniversitat in Leoben. His research focuses on the utilization of sensor based sorting equipment in order to separate valuable particles (e.g. metals or plastics) from landfill material during mechanical processing. He studies the influence of defilements on sensor based sorting and on wet-mechanical treatment in order to reduce defilements, creating high quality recyclable material. If he’s not in the university’s lab’s, you can most probably find him trail running, swimming or rock-climbing. |