ESR11

Guilherme Ascencão

Email: ; LinkedIn

I am in charge of engineering building materials converting vitrified solid residues derived from the thermochemical conversion of RDF (WP2) into raw materials to produce innovative value-added low-carbon products. Upcycling such residues will represent a sustainable value-chain solution. Within the scope of my project a reusable and recyclable composite, that is both heat insulating and responsive to temperature fluctuation, will be developed. The targeted properties require a final composite featuring layers of AAM that alternately present tailored porous microstructure and PCMs inclusion.

Problem statement & objectives

Alkali-activated materials have been extensively investigated, but different levels of scientific understanding and industrial implementation can be found among different subgroups of such materials. The most widely examined alkali-activated materials are commonly known as geopolymers. The scientific knowledge of their reaction mechanisms and structures is mature, and their market implementation fairly consolidated. Conversely, inorganic polymers (IP) are a different subgroup of alkali-activated materials since their chemistry does not exactly correspond to the definition of geopolymers. These systems are far more challenging but considerably more versatile. Unlike geopolymers, inorganic polymers can admit a wide range of precursors offering an opportunity to valorise low-value raw materials that include several wastes and industrial by-products. The diversity of precursors that can be used in IP production hinders the definition of production guideposts, and dedicated research is needed to define ad hoc solutions according to the characteristics of the considered precursors’ and envisioned applications.

Methods

The research was focused on the multiscale development of inorganic polymers and on the conceptual design of sustainable and multifunctional materials for near-zero energy buildings. Vitrified residues produced during the thermochemical conversion of refused derived fuel were taken as a representative case study of a broad group of currently underutilized industrial by-products, namely Ca-Fe-rich slags. The aim of this work was to understand the fundamental processing parameters affecting the reaction mechanism involved in the formation of Ca-Fe-rich IPs and their correlation with the final properties of the developed materials. The major technological constraints related to the use of such slags as IPs precursors were examined and the most suitable production conditions to obtain IP products with enhanced properties were identified.

Results obtained

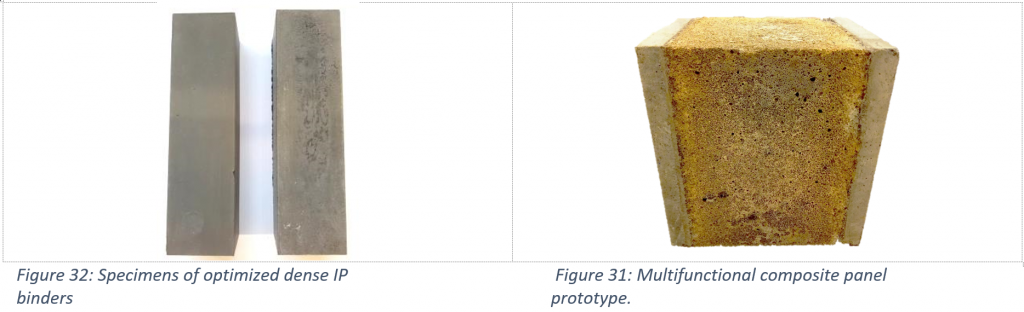

A broad range of IP materials with engineered properties were produced and optimized. Significant efforts were made in developing predictive models, in optimizing mixture proportions and in minimizing the shrinkage of IP binders and mortars. Optimized products characterized by a high dosage of residues in their composition (> 90 wt% of solids), increased volumetric stability, excellent mechanical properties, and good residual characteristics after exposure to high temperatures were developed. The functionalization of IP mortars was addressed, and the effects of incorporating phase change materials (PCM) in the mix design investigated. Lightweight IPs were developed using different processing routes, and their mechanical and thermal properties examined.

The main insights provided in each of the above-mentioned topics can be briefly summarized as follows: Several compositional factors affect the reaction kinetics and structural development of Ca-Fe-rich IPs being the solid-to-liquid and K2O/SiO2 ratio the most influential ones. The introduction of soluble silicates in the activating solutions positively impacts the reaction kinetics and favours the formation of denser microstructures, with a positive repercussion on the binder’s mechanical performance. Those governing factors were used to build predictive models and design IP binders with enhanced properties; i.e. low open porosity and water absorption (<5%) and high flexural (up to 7 MPa) and compressive strength (up to 175 MPa). However, high shrinkage values were observed, and significant efforts were devoted to describing such mechanisms and to the development of adequate mitigation strategies. Drying shrinkage was identified as the governing mechanism, whereas autogenous shrinkage was largely affected by the type of residue used.

Calcium-rich admixtures were found to be a simple and relatively inexpensive method to minimize shrinkage. Increasing dosages up to 3.0 wt% were able to reduce shrinkage by more than 60 %. Shrinkage reduction was proportional to the admixture content, but high dosages considerably impaired setting times and have a detrimental impact on IP microstructure. Therefore, an optimal dosage of 2.0 wt% is recommended to alkali-activated systems similar to those investigated. Slag’ partial replacement by reactive Ca-rich admixtures was also investigated. At room temperature, introduction of ground granulated blast furnace slag (GGBFS) into the mixture design was detrimental but such effects could be reverted if heat-curing was provided and strength development and volumetric stability greatly enhanced.

To summarize, providing extra Ca sources beneficiates the volumetric stability of IP products but the potential of such shrinkage mitigation strategy might be limited by the reactivity of the precursors.

Conversely, the use of organic compounds as shrinkage reducing agents is not constrained by the precursors' nature as their impact in the reaction kinetics is limited. These compounds significantly reduce the tensile stress from capillaries, resulting in more stable inorganic polymers. An increase in porosity results in a significant decay in mechanical properties, which, however, can be minimized with curing regimes at slightly elevated temperatures. Among the examined compounds, 2-Methyl-2.4-Pentanediol was found to be the more effective shrinkage reducing agent and having limited detrimental effects to strength development.

The principle of maximal content of slag was extended to the aggregates used to further increase the sustainably of the solutions proposed. Slag granules were processed and used to replace sand. Reactive aggregates do not behave as sand analogues as they take an active role in polymerization. Their partial dissolution enhances the reaction kinetics with the net effects of reducing setting times, increase strength development, and slight impair on the mortars’ volumetric stability. Nevertheless, the mortars produced revealed interesting properties, which can increase the competitiveness of developed materials. By combining multiple shrinkage mitigation strategies, highly dense mortars with a total slag content that excessed 85 wt% were developed presenting low shrinkage values (≈ 1 mm/m) and high flexural (up to 8 MPa) and compressive strength (> 55 MPa). Apart from allowing to maximize the slag dosage in the mix design and to optimize final properties, the key output of these investigations was a set of insights provided on the shrinkage mechanisms affecting AAMs and on the efficiency and effects of several shrinkage mitigation strategies that can now be tested on similar alkali-activated systems.

A different line of research was dedicated to the development of insulation materials from alkali-activated binders. Given the multitude of processing routes proposed in literature, an historical analysis was firstly conducted to identify the most promising ones. Based on such assessment, pre-made foams, in-situ foaming, and lightweight aggregates were used to produce thermal insulating lightweight materials with a broad range of properties. The parameters affecting each processing route were examined, and the materials were optimized in terms of apparent density, compressive strength and thermal conductivity.

The use of small-size lightweight aggregates was found the most adequate to develop insulating AAMs able to be compliant with structural requirements. The optimized materials presented compressive strength exceeding 4 MPa, apparent density near 0.50 g/cm3 and, thermal conductivity lower than 0.10 W/m°K. For non-structural purposes, the combined use of gas releasing, air-entraining, and stabilizing agents was found promising. By adequately tailoring the mix design, IPs could be engineered to present extremely low apparent density and thermal conductivity, 280 kg/m3, and 0.06 W/m°K, respectively. The developed materials showed self-bearing capacity, but their use in applications where significant loads are foreseen will be challenging.

The production of multifunctional thermally reactive IP mortars was also explored.

The addition of PCM to the mortar’s formulation could effectively reduce temperature gradients, proving thermal buffering features to the developed materials. Such results indicate that IPs can be functionalized to act as passive thermal regulators able to guarantee adequate levels of comfort in near-zero energy buildings.

The high-temperature resistance of the developed AAMs was also demonstrated. The results have shown that IP mortars have superior thermal performance relative to those of mainstream construction materials. Post-heating properties are determined by the maximum temperature of exposure and heating rate. Lower heating rates have a beneficial effect on AAM's mechanical performance, while steepest heating processes promote severe deterioration processes and result in extensive crack development. Those harmful effects limited the use of the developed materials to 900 °C if high heating rates would be experienced. Nonetheless, independently of the heating rate tested, the thermal features of benchmark materials (e.g., OPC-based products) were clearly surpassed.

Finally, a precast multifunctional composite panel was produced. The motivation for this research was to develop highly performant sustainable sandwich panels with the potential to replace conventional precast insulating solutions. The challenge was to demonstrate the feasibility of producing thermally-responsive and insulating sandwich panels at a semi-industrial scale and to identify possible criticalities in future upscaling stages. The production of optimized IP mortars, with or without phase change materials, was shown to be a robust process that does not suffer significant scaling effects. Conversely, the production of foamed IPs was found to be more sensitive to scaling, which can be challenging in industrial contexts.

Conclusion & Outlook for further work

The so far largely neglected potential of Ca-Fe-rich slags was highlighted within this research by demonstrating that they can be successfully reintegrated into the materials cycle via alkali-activation in the form of sustainable and add-valued building materials. However, the development of highly performant and multifunctional inorganic polymers is not trivial and requires a profound understanding of the factors influencing the properties of end products. The analysis and description of Ca-Fe-rich IPs is challenging, and little work has been previously undertaken to streamline early investigations into industrial contexts. By exploring the development of alkali-activated products with a wide range of properties on a multiscale level, a solid scientific basis was provided for future scaling-up developments.

The topic analysed in this research and the insights provided are particularly interesting to the construction sector in which current efforts to achieve lower environmental impacts are considerable. The use of Ca-Fe-rich slags in such production schemes is a plausible large-scale upcycling route that can absorb significant volumes of those residues and, by doing so, contribute to increasing the sustainability of industrial sectors in which such residues are produced, e.g. enhanced landfill mining.