ESR3

Bastian Küppers

Email: ; LinkedIn

I work on the utilization of sensor based sorting equipment in order to separate valuable particles (e.g. metals or plastics) from landfill material during mechanical processing. Thereby the defilements complicate the sorting in particular. Therefore I will study the influence of defilements on sensor based sorting and work on wet-mechanical treatment in order to reduce defilements, creating high quality recyclable material. Any questions or wishes? You can write me an e-mail at .

Problem statement & objectives

In the past, landfill mining has been conducted with simple processing technology to keep specific processing costs down, yielding low value output fractions. The concept of enhanced landfill mining focuses on the production of high-quality output fractions, targeting improved economic efficiency. Sensor-based sorting machinery can contribute to this by material-specific separation of exploitable fractions. As a result, the production of marketable products is increased, reducing the share of landfill space that is occupied by these materials. The main challenge of implementing sensor-based sorting in enhanced landfill mining is the high degree of impurities, adhesions and contaminations in landfill material. This can inhibit the functioning of sensor-based sorting technology.

Methods

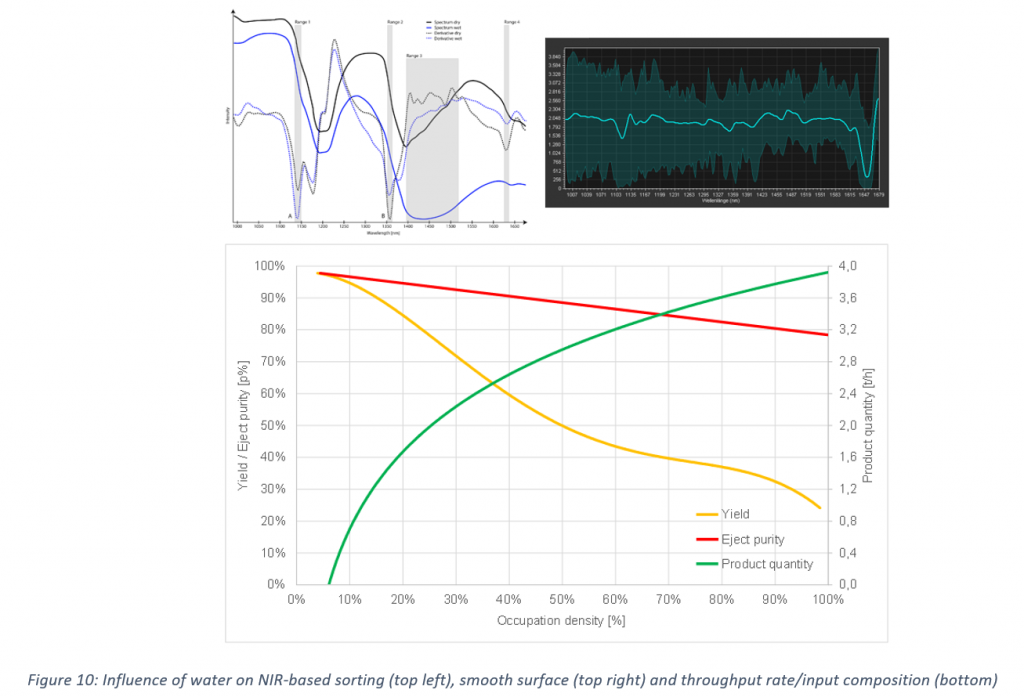

To study the most relevant impurities for sensor-based sorting, the material streams that show potential for such sorting technologies in mechanical processing of landfill material were identified: heavy fractions from air classification and 3D fractions from ballistic separation. Since near-infrared technology was found to be suitable for this sorting task, the most decisive factors that affect the selected spectral information and are therefore essential to make sorting decisions, were studied in detail: surface roughness and humidity.

In addition, the effects of input composition and throughput rate on sorting performance were quantified to gain a more comprehensive understanding of their relevance for sensor-based sorting stages and to determine potential for their improvement. By implementing the knowledge gained in these studies, the separation of combustibles and inert materials and the differentiation of various plastic types were carried out.

Results obtained during the reporting period

Increased surface roughness proved to enhance particle classification, while water absorbs near-infrared radiation and alters the material-specific spectral fingerprint of near-infrared active materials. This effect can be counteracted by adjustments in the sorting algorithm. Furthermore, first tests on the effect of thick oxide layers on x-ray fluorescence-based sorting were conducted and indicated technological feasibility for the application to landfill mining.

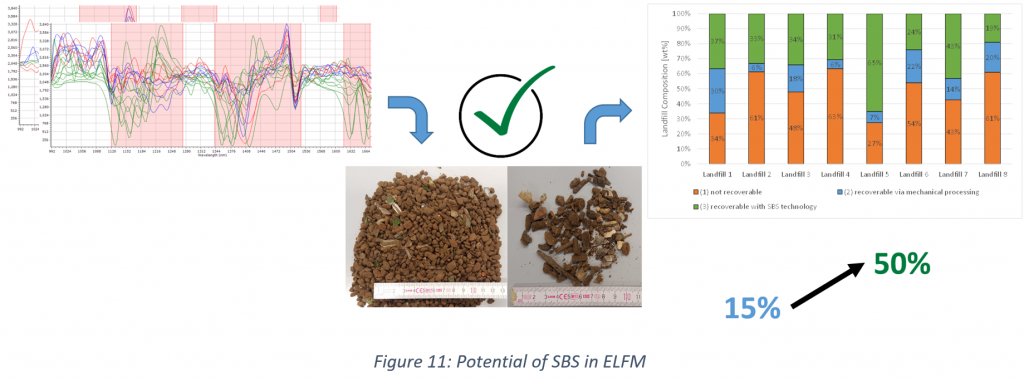

In sorting experiments with landfill material the yields of polyethylene, polypropylene and polyvinylchloride from the Halbenrain landfill were higher than 90 wt%. Therefore, if successfully applied to enhanced landfill mining, sensor-based sorting technology could enable the recovery of 35 wt% of landfilled material in addition to approximately 15 wt% that could be unlocked with conventional mechanical processing technology on average in Europe. Depending on local legislation, additional treatment steps as washing might be necessary to enable energy production or material recycling from the respective output fractions.

In sorting experiments with landfill material the yields of polyethylene, polypropylene and polyvinylchloride from the Halbenrain landfill were higher than 90 wt%. Therefore, if successfully applied to enhanced landfill mining, sensor-based sorting technology could enable the recovery of 35 wt% of landfilled material in addition to approximately 15 wt% that could be unlocked with conventional mechanical processing technology on average in Europe. Depending on local legislation, additional treatment steps as washing might be necessary to enable energy production or material recycling from the respective output fractions.

Conclusion & Outlook for further work

For a comprehensive assessment of XRF sorting technology further in-depth experiments are necessary. The long-term stability of sensor-based sorting machinery in enhanced landfill mining has to be proven in large-scale tests.